Filling the Gap: How a Small Innovation Enabled Brightline to Create America’s First Private High Speed Rail Service

Brightline, the private high speed rail service in Florida has received a great deal of buzz lately. From their tentative launching of revenue service in the next few weeks to the Feds giving them the greenlight for the Orlando extension it’s looking more and more like they might actually pull the project off.

Since the broad strokes of the project have been discussed at length elsewhere, I wanted to add to the discourse by deep diving on a novel, seemingly small innovation that has allowed this entire project to exist — the retractable gap filler

Florida East Coast industries, The parent company behind Brightline, is a freight operator. They are Florida’s oldest and largest commercial real estate, transportation, and infrastructure holding company. They have owned and operated freight service on the corridor since 1888 when Henry Flagler of Standard Oil purchased the Jacksonville, St. Augustine and Halifax River Railway. When Florida East Coast introduced passenger service to its corridor, it had to not interfere with the existing freight operations. This sounds logical — new trains equate to increased traffic which then equals adding capacity- This however leaves out a critical piece of new infrastructure, stations.

Stations prove to be quite problematic on mixed traffic corridors. The ideal station from a passenger service standpoint are those with train level platforms that are flush with the cars. This not only makes the train accessible, but also significantly increases the efficiency of boarding and reduces dwell time in station. The problems is that in most cases, constructing a train level station platform makes that track impassable by freight traffic.

Freight cars have variable widths and need more clearance to be operational. To accommodate this, the most commonly employed solution is to build the station platform at ground level, but then passengers are left to climb steps or use a stool to board the train itself. While this alleviates the clearance issue, it also substantially decreased the station’s usability and performance.

NC Piedmont Train

This is the case for most of the stations in my home state of North Carolina. All but one station is constructed in this fashion because the NCRR corridor that our passenger trains operate on also serve substantial freight traffic from Norfolk Southern.

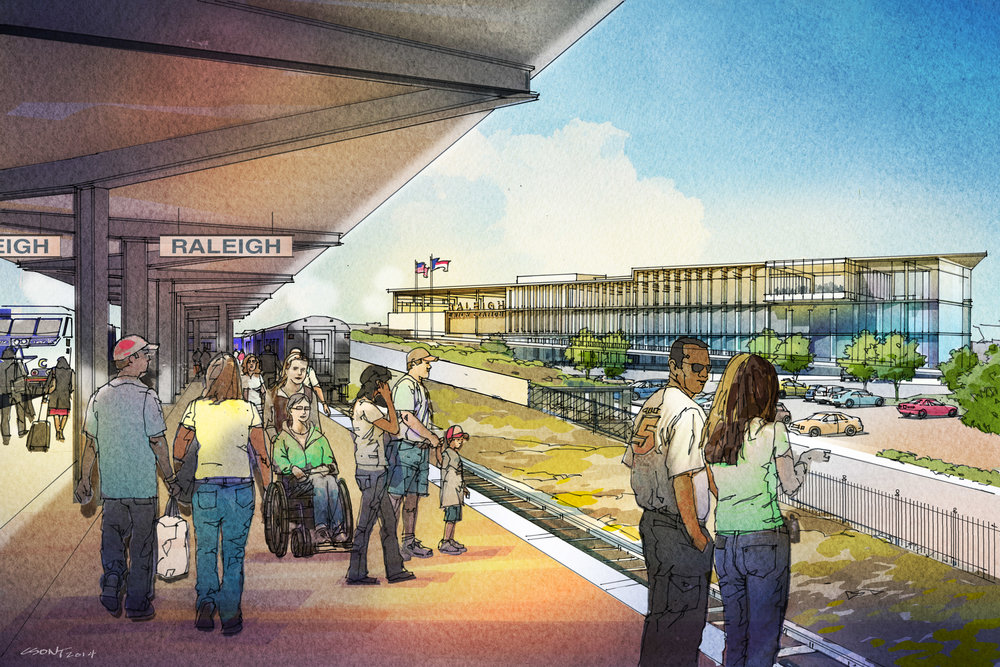

The notable exception is the new Raleigh Union Station which is slated for completion in early 2018. It will feature two current and four future platforms at train level. This is only the case because the track in which the platforms lie is off the main line and thus doesn't have to worry about freight clearance issues.

While there is a workable solution in places that can accommodate the train, it is far from a universal applicable tool. The stark reality is that space and cost constraints make this an unpractical to implement in most cases. Thus most stations that aren’t on dedicated corridors are built at ground level. This is where the brilliance of the retractable gap filler enters the equation.

To solve the conundrum above, Florida East Coast Industries and their train-set manufacture Siemens collaborated with Bodeo to develop a custom gap filler that is integrated directly into the train car door system. When at the station, the system extends out to create a flush connection with the platform.

While creating a superb passenger experience was certainly a strong consideration in creating this solution, I suspect a far more important factor was allowing freight traffic to run through station track. You see with the addition of the gap filler, the platform can be constructed with the necessary clearance to allow freight trains to operate unimpeded. This may seem like a small change, but where corridor width is limited it can make all the difference in the world. It allows mainline track to run through a station and sever all traffic. The innate cost savings derived from not having to build bypass track allows for platform level station to make their way into the mainstream of American rail infrastructure.

Out of context, the below video is unremarkable — A FEC freight train is simply passing through the West Palm Beach station. The banality of this scenario masks the the monumental impact it is set to have.

While the retractable gap filler may seem like an inconsequential innovation, it represents a meaningful stride toward making passenger rail work in the US context. We operate in an environment without the luxury of dedicated passenger-only track and have to think about building better service different then the well funded and heavily trafficked systems of Europe and Asia. It’s innovations like this that alone, make travel better, but together, compound to make meaningful and tangible improvements to how we travel.

It’s innovations like the one above that, alone, make travel better, but together, compound to make meaningful and tangible improvements to how we travel.